The Quiet Evolution of Thermal Interface Materials

In the perpetually overheating world of high-performance computing, an unsung hero works tirelessly between your CPU and its heatsink. Thermal interface materials—those seemingly insignificant layers of paste, pad, or liquid metal—make the difference between a smoothly running system and a throttling, crash-prone machine. While enthusiasts obsess over processor cores and graphics card specs, these microscopic gap-fillers have undergone their own technological revolution, enabling the performance leaps we take for granted. As processors generate more heat in smaller spaces, these materials have evolved from simple grease to engineered compounds that challenge our understanding of thermal conductivity at the microscopic level.

Beyond the Squeeze: Understanding Thermal Interfaces

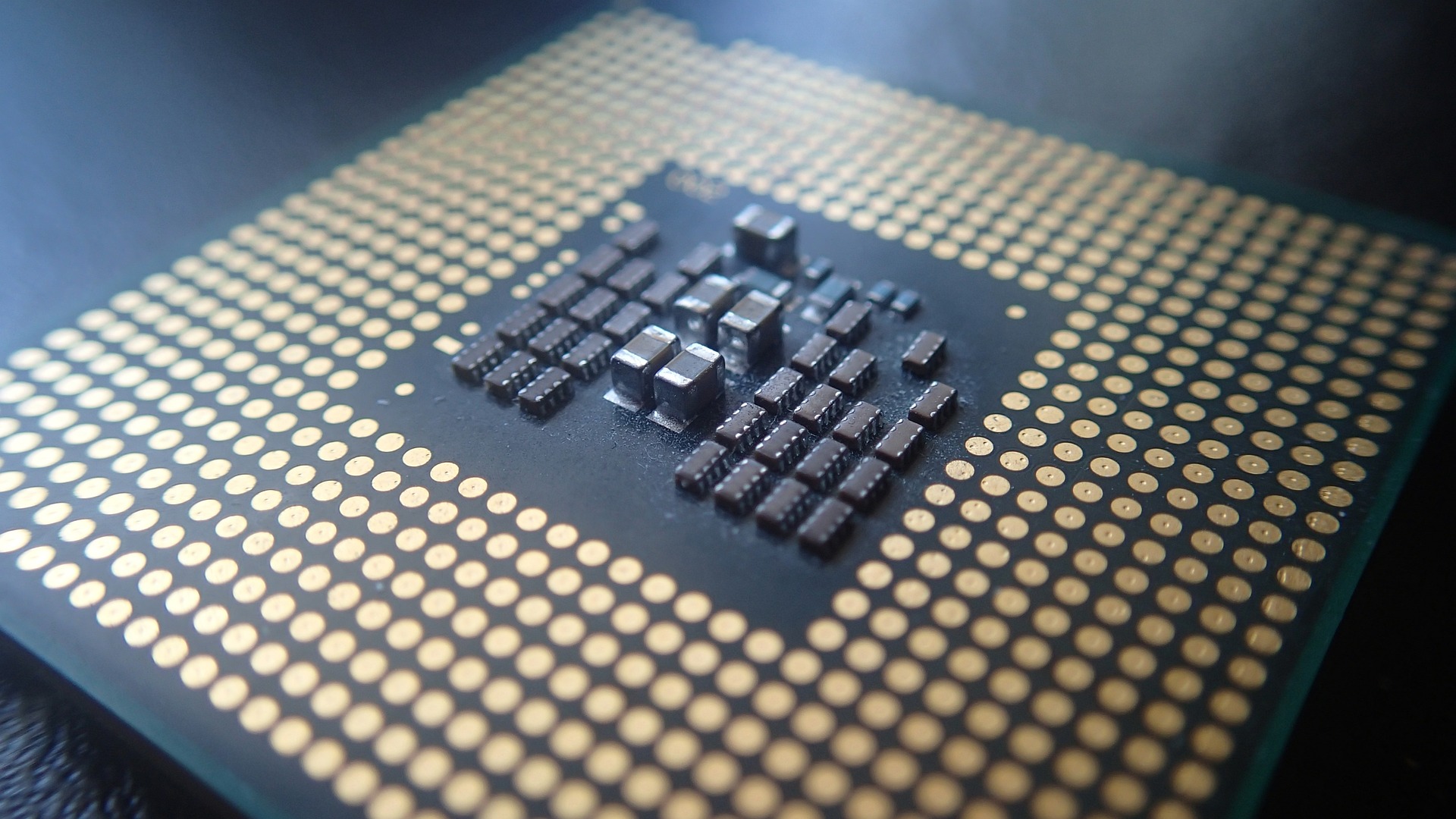

The fundamental problem thermal interface materials (TIMs) solve is deceptively simple: CPU and GPU dies aren’t perfectly flat, and neither are heatsinks. Under a microscope, both surfaces resemble mountain ranges, with peaks and valleys that trap performance-killing air when pressed together. Air is an excellent insulator—great for your coffee thermos, terrible for processor cooling.

Early thermal compounds were basic zinc oxide-based greases that simply displaced air from these microscopic gaps. Today’s materials employ sophisticated carbon nanostructures, liquid gallium alloys, and phase-change compounds that transform from solid to liquid at specific temperatures. The best modern TIMs conduct heat up to 73 W/mK (watts per meter-kelvin), compared to around 5 W/mK for premium pastes from just a decade ago.

Researchers at the University of Illinois recently demonstrated that the contact area between a processor and heatsink without thermal material is typically less than 1% of the total surface area. A quality thermal interface material increases this to over 90%, explaining why your expensive processor would quickly fail without this crucial intermediary.

The Liquid Metal Revolution

In 2019, a significant shift occurred when AMD began using liquid metal compounds in their high-end processors. These gallium-based alloys conduct heat five to ten times more effectively than traditional pastes but were previously considered too risky for mainstream use. Liquid metal’s electrical conductivity means any spillage could short-circuit components, and its tendency to amalgamate with aluminum makes it incompatible with many heatsinks.

Intel followed suit with their 11th and 12th generation processors, utilizing liquid metal TIMs under the integrated heat spreader. This seemingly minor change allowed for temperature reductions of 5-7°C under load—a significant improvement that enabled higher sustained boost clocks without additional cooling hardware.

System builder Dustin Sklavos notes, “Liquid metal represented a genuine paradigm shift for thermal solutions. The industry had been incrementally improving pastes for decades, but liquid metal’s adoption by major manufacturers legitimized a technology enthusiasts had been cautiously experimenting with for years.”

The liquid metal market has grown from $15 million in 2018 to an estimated $78 million in 2023, with costs to consumers dropping from around $20 for a single application to under $10 today.

Carbon Nanostructures: The Next Thermal Frontier

While liquid metal captured headlines, a more fundamental revolution has been brewing in materials science labs. Carbon-based thermal materials—utilizing graphene, carbon nanotubes, and diamond particles—are demonstrating thermal conductivity rates that approach theoretical limits.

Researchers at MIT and the University of Michigan have developed graphene-enhanced thermal compounds that achieve up to 14 W/mK in commercial formulations—nearly three times better than premium conventional pastes. More experimental compounds using aligned carbon nanotube forests have demonstrated an astonishing 200 W/mK in laboratory settings.

The real breakthrough isn’t just the raw thermal performance but the way these materials conform to surface irregularities. Traditional compounds simply fill gaps; carbon nanostructures actively conduct heat through molecular bonds that form temporary connections between surfaces. This allows for more efficient heat transfer even when mechanical pressure isn’t perfectly applied.

Industry pricing remains high—around $30-40 for a small syringe of premium carbon-enhanced compound—but manufacturing scale-up is rapidly driving costs down. Market analysis firm TechInsights forecasts carbon-based thermal interfaces will dominate the high-performance segment by 2025.

Thermal Pads: The Unsung Workhorses

While enthusiast attention focuses on CPU and GPU thermal compounds, the broader electronics industry has been quietly revolutionizing thermal pads—the flexible, often blue or pink sheets found cooling memory chips, VRMs, and other components.

Modern thermal pads utilize phase-change technology that softens precisely at operating temperatures, conforming to component surfaces without the mess of pastes. The latest generation incorporates fiberglass mesh reinforcement, preventing the compression and pumping-out effect that plagued earlier designs.

Thermal pad performance has improved from around 3 W/mK to over 15 W/mK in premium products, with thickness options ranging from paper-thin 0.5mm to gap-filling 3mm variants. This flexibility has enabled the increasingly dense component layouts in modern electronics, particularly in the space-constrained environments of gaming laptops and smartphones.

The global thermal pad market reached $1.2 billion in 2022, with prices ranging from $10 for basic options to over $50 for premium silicone-free, electrically-insulating variants used in sensitive applications.

Application Science: It’s Not Just What You Use, But How You Use It

Perhaps the most significant yet least discussed aspect of thermal interface technology is application methodology. The “pea method” versus “spread method” debates that once dominated enthusiast forums have given way to more sophisticated understanding of how different TIM formulations should be applied.

High-viscosity pastes perform best with specific pressure patterns, while liquid metal requires meticulous application to prevent electrical shorts. Phase-change materials need specific temperature cycles to achieve optimal performance, and some newer compounds actually improve conductivity after several thermal cycles.

Manufacturers have responded with increasingly sophisticated applicators—from the credit-card spreaders of yesterday to today’s precision syringes with specialized tips designed for specific processor geometries. Some premium compounds now ship with application stencils calibrated for popular CPU socket types.

Testing by GamersNexus revealed that improper application can negate the benefits of even the most advanced thermal materials, with temperature differences of up to 12°C between optimal and suboptimal application of the same compound.

As processors continue to generate more heat in smaller packages, these often-overlooked thermal intermediaries will only grow in importance. The quiet evolution happening between chip and heatsink may lack the marketing glamour of core counts and clock speeds, but it remains an essential enabler of the performance we’ve come to expect from modern computing.